[Top]

[Up]

[Prev]

[Next]

Semi-Rigid Main Rotors

A semi-rigid main rotor is always a 2 bladed rotor system. It gets its

name from the fact that it does not have a lead-lag hinge, the way a fully

articulated rotor system does. The rotor system can be said to be rigid

in-plane, because the blades are not free to lead and lag, but they are

not rigid in the flapping plane (through the use of a teeter hinge).

Therefore the rotor is not rigid, but not fully articulated either, so we

call it semi-rigid.

The rotor systems we will look at here are 2 bladed teetering systems. The

Robinson and the Bell teetering system differ because the Robinson includes

coning hinges in addition to the teeter hinge, while the Bell system simply

cones by bending the blades.

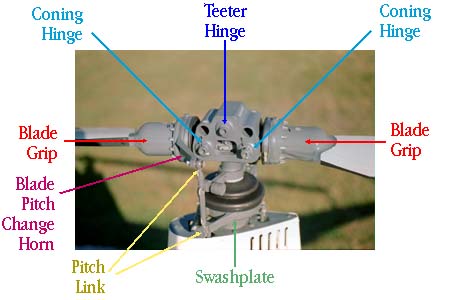

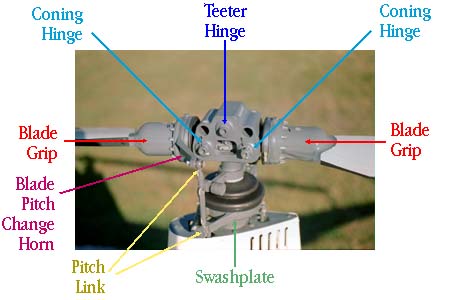

Basic R22 Head

Teeter Hinge

The dark blue arrow is pointing to the teeter hinge. This central hinge

allows the entire rotor head to tilt left and right in order to allow the

blades to flap. When one blade flaps up, the other flaps down. The entire

mechanical arrangement works like a child's see-saw (teeter-totter) toy.

Coning Hinge

The light blue arrows point to the two coning hinges. These hinges allow

each blade to move up and down independently of the other blade. This would

normally happen during coning, when each blade moves up until centrifugal force

balances lift. During times of high lift, or low RPM, the blades will be

coned quite high, while during low lift or high RPM, the blades will tend to

be lower.

The holes in the rotor head above the coning hinges serve no purpose except

that they may be used to hoist the rotor system.

Blade Grips

The light red arrows point to the blade grip. The grip attaches the

rotor blade to the rotor head, and includes a pitch change mechanism used

to change angle of attack by feathering the blade (with the cyclic control).

In the case of the R22, the grip has multiple bearings, and is filled with

a fluid similar (identical?) to automatic transmission fluid.

Pitch Horn

The dark red arrow points to the left hand blade pitch horn. The pitch

horn on the right blade is behind the head in this photograph can cannot be

seen, but does exist. The purpose of the pitch horn is to give the feathering

pitch change mechanism (cyclic/swashplate) a place to attach to the blade.

By sticking out from the blade, the pitch horn works as a lever, decreasing

the force it takes to change the angle of the blade. Note that it also has

the effect of changing the location on the swashplate where the pitch

mechanism attaches. Rather than attaching to the swashplate directly under

the blade, it attaches to the swashplate almost 90 degrees earlier in rotation.

This is how the control system corrects for the almost-90 degree lag in rotor

response due to Gyroscopic Precession.

Pitch Link

The yellow arrow points to the pitch link, which connects the pitch horn

to the swashplate. These length of these pitch links can be adjusted to set

the angle of incidence of the blade during track and balance of the rotor

system.

Rotating Star (Swashplate)

The green arrow points to the rotating portion of the swashplate, which

attaches to the pitch links. Below that is the non-rotating part, which

connects to the pitch control rods coming up from the cyclic/collective

mixer.

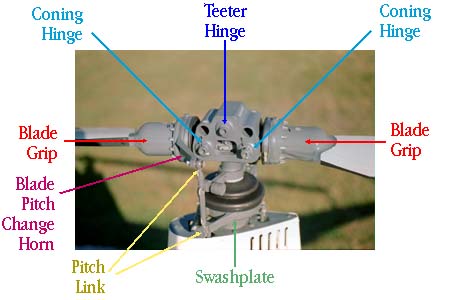

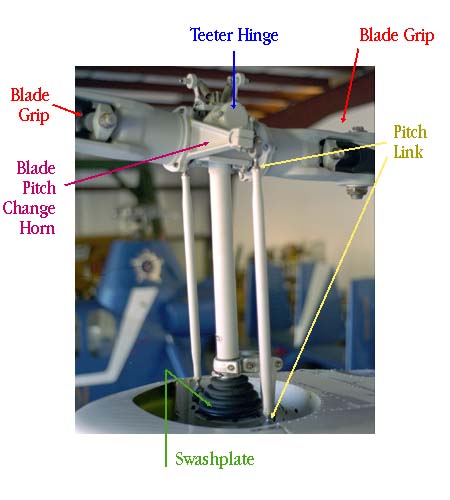

Basic JetRanger (Bell 206) Head

The design of the Bell 206 rotor head is not that different from that of

the Robinson. Note that in this picture, there are no light blue arrows,

because the 206 head does not include coning hinges. Instead, the rotor

head is designed with a pre-cone angle to the blade retention system, and

other coning forces are simply dealt with by bending of the blades (which

must be built stronger to deal with the extra stress).

Blade Grips

The light red arrows point to the blade grips. The design is slightly

different than the Robinson. The inside of the grips is filled with a light

grease, rather than a fluid. Also, note on the right hand blade that there

is a vertical bolt attaching the blade to the grip. The blade can be set

with some fixed lead or lag as part of the rotor system rigging, compared

to the Robinson where the lead/lag position of the blade is fixed by the

design of the rotor head, and can not be adjusted, even at the factory.

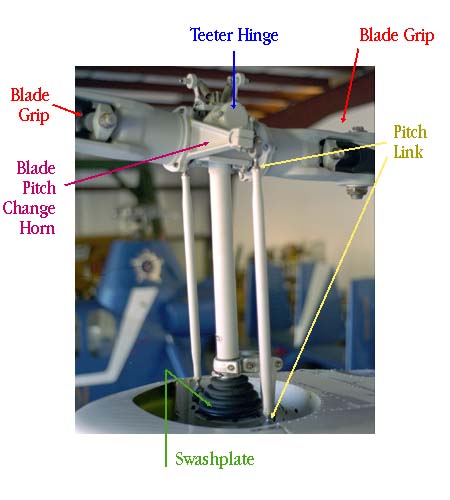

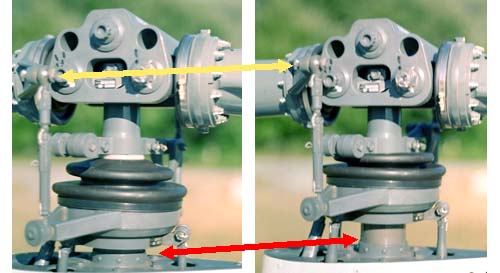

What is Teetering (Flapping) versus Feathering?

On any rotor system, flapping occurs when the blade moves up and down. On

a rigid rotor system, this occurs when the blade bends. On an articulated

system, the blade flaps up and down around a flapping hinge. On a

2 bladed, semi-rigid teetering system, the blades flap in unison around

the flapping hinge such as in these pictures of a Robinson R22:

Notice that the angle the airfoil makes with the horizon here does not change.

Flapping changes the angle of attack not by pitching the airfoil up or down,

but by changing the direction of the wind relative to the blade. For a more

in-depth discussion see Relative Wind,

Flapping and

Angle of Attack.

Compare this to the following picture which shows the blade being feathered

by the pilot's controls via the swashplate:

In this picture, you can clearly see that the angle of the blade with respect

to the horizon has changed, from a nose up angle on the left side, to a nose

down angle on the right side. In this case, the swashplate has moved in

response to either the cyclic, collective, or both, and has moved the pitch

links up or down. Since the pitch links are connected to the blade via the

pitch horn, the blade is forced to rotate around the blade grip bearing

into a different angle

of incidence.

How does the Rotor System Teeter?

The rotor system teeters around the central hinge. The position of the

blades is due to the balance between centrifugal force which is trying

to hold the blades "straight out", versus lift which is trying to make

them fold straight up. The balance of the forces will cause the blades

to fly at some angle. If one blade starts to develop more lift, while

the other blade starts to develop less lift, one blade will want to climb

while the other will want to descend. The result will be that the rotor

head will teeter, allowing one blade to go up while the other goes down.

It is important to understand that teetering happens "automatically", as

a result of aerodynamic and centrifugal forces. The pilot does not command

flapping with the control system.

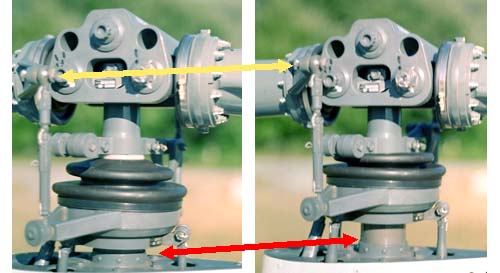

How does (the R22) Control System Transmit Pitch to the Blades?

There are many different mechanisms for transmitting cyclic and collective inputs

to the main rotor system. The Robinson R22 and R44 mount the swashplate on a

monoball. This allows the entire swashplate to slide up and down on the

rotor mast (for collective inputs) and tilt (for cyclic inputs).

These two pictures show how the swashplate slides up and down to transmit

a collective pitch change:

You can see that the red arrow is pointing to the bottom of the swashplate

in the left hand picture, but that in the right hand picture the entire

swashplate has moved up the mast. Notice the effect that has on the pitch

links: the yellow arrows show that in the right hand picture, the pitch

link has moved up along with the swashplate (compare the top of the pitch

link and the left hand coning hinge bolt in the two pictures). Since the entire

swashplate has moved up without changing its tilt, the pitch links have all

moved up a set amount, but will continue to move up and down during rotation

in response to the tilt of the swashplate.

In comparison, look at the following picture to see how cyclic input is

transmitted to the blades:

Notice that the swashplate in the left hand photograph is basically level,

while in the right hand photograph it has been tilted. The tilt will cause

the pitch link to have to move up as it travels to the right hand side of the

picture, and move back down as it travels to the left hand side of the picture.

As it moves up and down the blade pitch will increase and decrease.

Paul Cantrell

paul at copters.com

(replace " at " with "@" to email me - this avoids SPAMMERS I hope)

[Top]

[Up]

[Prev]

[Next]